Stahlin Enclosures, manufacturers of high performing fiberglass electrical and industrial enclosures, provides nearly seven decades of reliable service to the remote monitoring device industry.

Stahlin Enclosures, manufacturers of high performing fiberglass electrical and industrial enclosures, provides nearly seven decades of reliable service to the remote monitoring device industry.

Craig Mitchell, President of Robroy Enclosures, explains:

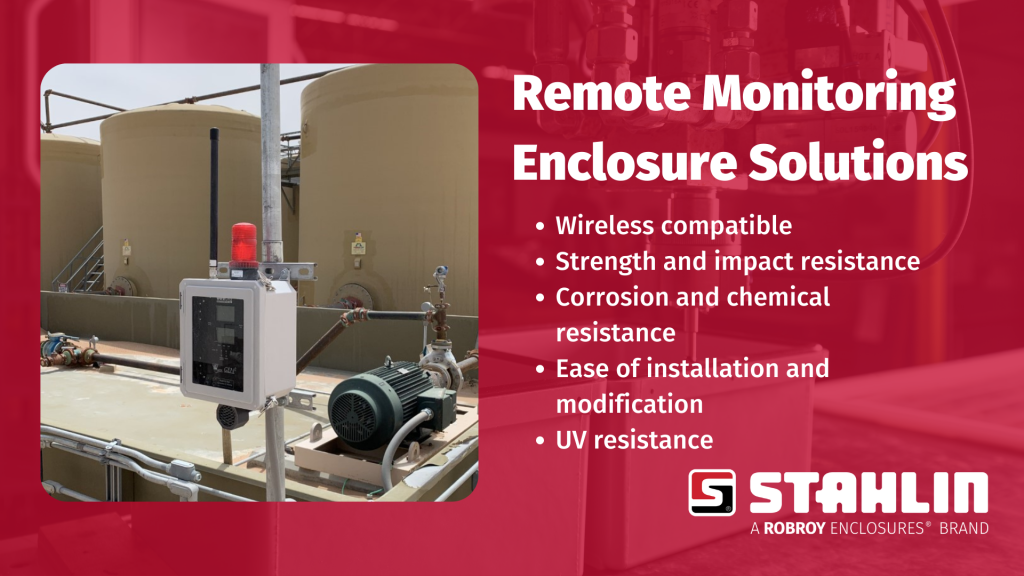

“Stahlin has been the market leader ever since we pioneered the first fiberglass enclosure almost 70 years ago. Our expertise is of particular value in demanding remote monitoring applications. The quality of Stahlin fiberglass enclosures is key to providing proven solutions where technology must be applied in remote, rural, or difficult-to-reach locations. This includes utilities, solar and wind installations, oil and gas fields, agribusiness, and many other applications where data interchange and diverse types of communications must be achieved without direct human-to-human interaction.”

As “proof of performance”, Stahlin Enclosures has released a case study showcasing how its non-metallic enclosures solve the challenge of providing proven protection for gas detection and remote monitoring systems: https://stahlin.com/case-study/providing-proven-protection-for-gas-detection-and-monitoring-systems/.

There are many reasons why Stahlin fiberglass enclosures are an ideal choice for remote monitoring applications, especially when compared to metallic alternatives.

Compatibility With Wireless Technology

Stahlin fiberglass enclosures are excellent for protecting wireless technology because they allow wireless and radio frequency signals to pass unobstructed through the enclosure. This allows the effective use of antennas inside of the enclosure. Additionally, there is the option to block EMI/RFI frequencies if needed, providing more flexibility than available from metal enclosures.

Strength

Stahlin fiberglass enclosures are made specifically for rugged applications requiring enclosure strength. Because fiberglass provides corrosion resistance and dimensional stability, Stahlin enclosures are reliable in remote monitoring applications within continuously demanding environments.

Impact Resistance

Upon impact, metal enclosures are vulnerable to denting which, along with aesthetic concerns can compromise the integrity of the seal that protects everything housed within the enclosure.

Corrosion and Chemical Resistance

NEMA type 4X Stahlin fiberglass enclosures provide proven resistance to corrosive environments where acids or alkalines are present. Because of excellent corrosion resistance, fiberglass meets the remote monitoring demands of diverse industries in wide-ranging environments.

Ease of Installation and Modification

Fiberglass, compared with metal enclosures is lightweight, making it easier and quicker to install; thereby being of value in overall cost reduction. Stahlin enclosures are also easy to modify, either at the manufacturer and delivered ready to use — or in the field using standard tools for cutting holes, windows, vents, and drains.

UV Resistance

We add Solarguard, our patented UV inhibitor, to all of our fiberglass enclosures so that they can weather the passage of time even in harsh exterior applications. Stahlin fiberglass enclosures carry an f1 rating for outdoor use per UL 746c.

Many industries are increasingly automated and dependent upon reliable remote monitoring technology. Because Stahlin fiberglass enclosures provide world-class performance in widely ranging environmental applications, they are ideal for protecting remote monitoring systems including

protection of widely-ranging instrumentation, sensor and monitoring units, control systems, measurement apparatus, real-time processing, and range/satellite telemetry devices.