Stahlin Enclosures is a leading manufacturer of non-metallic enclosures featuring high-performing fiberglass and polycarbonate enclosures.

The on-the-job performance benefits of non-metallic enclosures versus metal enclosures provide users the best choice in value because of these proven facts:

FACT ONE: NON-METALLIC ENCLOSURES PROVIDE THE GREATEST COST SAVINGS

Stahlin non-metallic enclosures in sizes 48 x 36 and below can be 20-30% more cost-effective than stainless steel and very competitive versus other metallic enclosures. Lighter-weight non-metallic enclosures bring users added cost savings on shipping and reduced labor times.

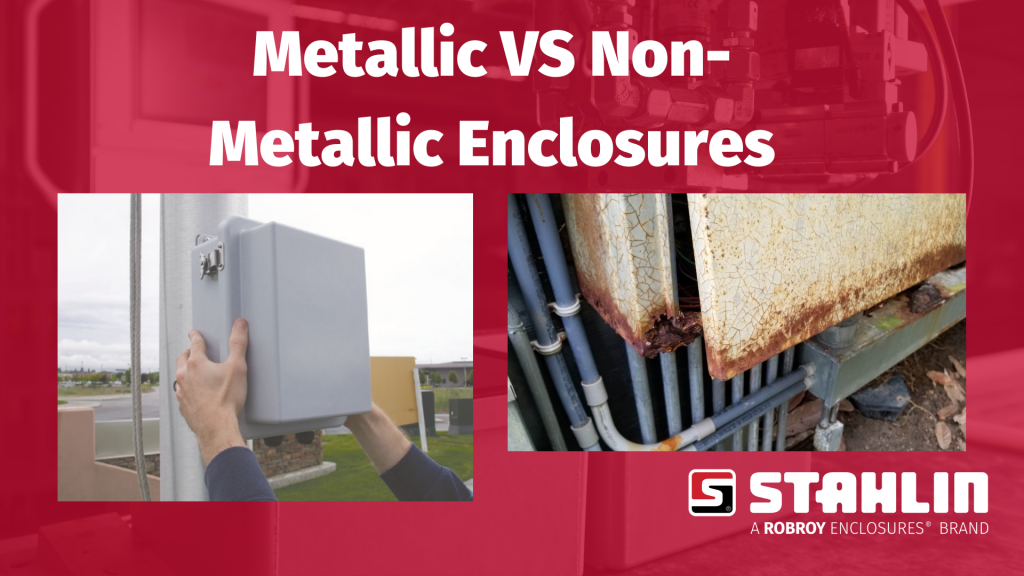

FACT TWO: NON-METALLIC ENCLOSURES PROVIDE THE BEST CORROSION AND CHEMICAL RESISTANCE

Non-metallic enclosures exceed the protection of aluminum, painted carbon, and galvanized steel when it comes to fighting the costly degradation of corrosion and the destructive properties of diverse chemicals.

FACT THREE: NON-METALLIC ENCLOSURES PROVIDE PROTECTIVE ELECTRICAL INSULATION

Stahlin non-metallic enclosures provide optimal dielectric strength as an electrical insulator versus the electrical conductivity of metal enclosures. When using non-metallic enclosures grounding is not required to ensure safety against indirect and direct contact.

FACT FOUR: NON-METALLIC ENCLOSURES ARE THE BEST CHOICE FOR EASIEST MODIFICATION

Non-metallic enclosures, compared to metallic options, are easy to customize. Using tools common to job sites non-metallic enclosures are simple to drill, punch, and cut compared to all metals. Through our ModRight enclosure modification program, we can use our factory-based expertise to provide diverse modifications including knockout panels, windows, silk-screening, digital printing, laser engraving, custom sizes, colors, and assembly. These modified enclosures will arrive when and where you need them, ready to use right out of the box.

FACT FIVE: NON-METALLIC ENCLOSURES ARE EASIER TO INSTALL

Compared with metal enclosures, Stahlin fiberglass and polycarbonate enclosures are lightweight, making them easier to handle and install.

FACT SIX: NON-METALLIC ENCLOSURES PROVIDE MAXIMUM PROTECTION THROUGH IMPACT RESISTANCE AND THE ABILITY TO MAINTAIN A PROTECTIVE SEAL

Metal enclosures are subject to the loss of sealing protection because gasket seals can be compromised even by small dents in the metal caused by impact. Impact resistance is the greatest attribute of polycarbonate. Both polycarbonate and fiberglass have the ability to flex with impact and not dent. The resistance to impact protects the integrity of the enclosure gasket and ensures a proper seal against moisture and contaminants, while providing reliable protection to the equipment within the enclosure.

FACT SEVEN: NON-METALLIC ENCLOSURES PROVIDE MAXIMUM UV RESISTANCE AND MAINTAIN MECHANICAL PROPERTIES IN OUTDOOR ENVIRONMENTS

Stahlin Enclosures patented Fiberglass SolarGuard SMC material formulation rated f1 with UL outperforms metal enclosures in outdoor environments by over 60% in maintaining mechanical properties such as gloss and color.