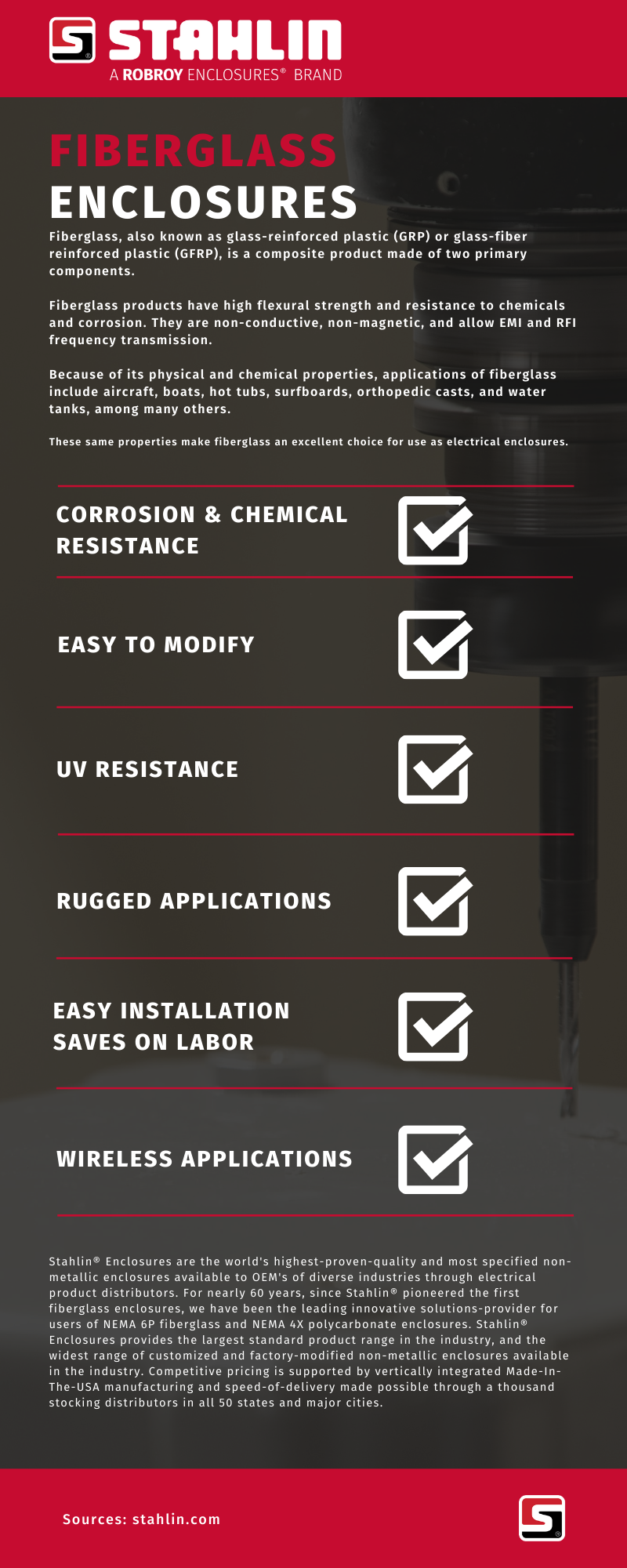

Fiberglass, also known as glass-reinforced plastic (GRP) or glass-fiber reinforced plastic (GFRP), is a composite product made of two primary components. A thermoset plastic, in this case an unsaturated polyester resin, and glass fibers are combined to create robust and corrosion resistant products.

In Stahlin enclosures, a polyester resin and other proprietary ingredients are mixed with glass fibers to add strength while adding minimally to the weight. This results in a material reading for molding, known as the sheet molding compound.

The sheet molding compound is placed on a steel mold and heat and pressure are applied for a few minutes depending on the size of the product. During this time, a chemical reaction takes place and the material is permanently set into place.

Fiberglass products have high flexural strength and resistance to chemicals and corrosion. They are non-conductive, non-magnetic, and allow EMI and RFI frequency transmission.

Because of its physical and chemical properties, applications of fiberglass include aircraft, boats, hot tubs, surfboards, orthopedic casts, and water tanks, among many others.

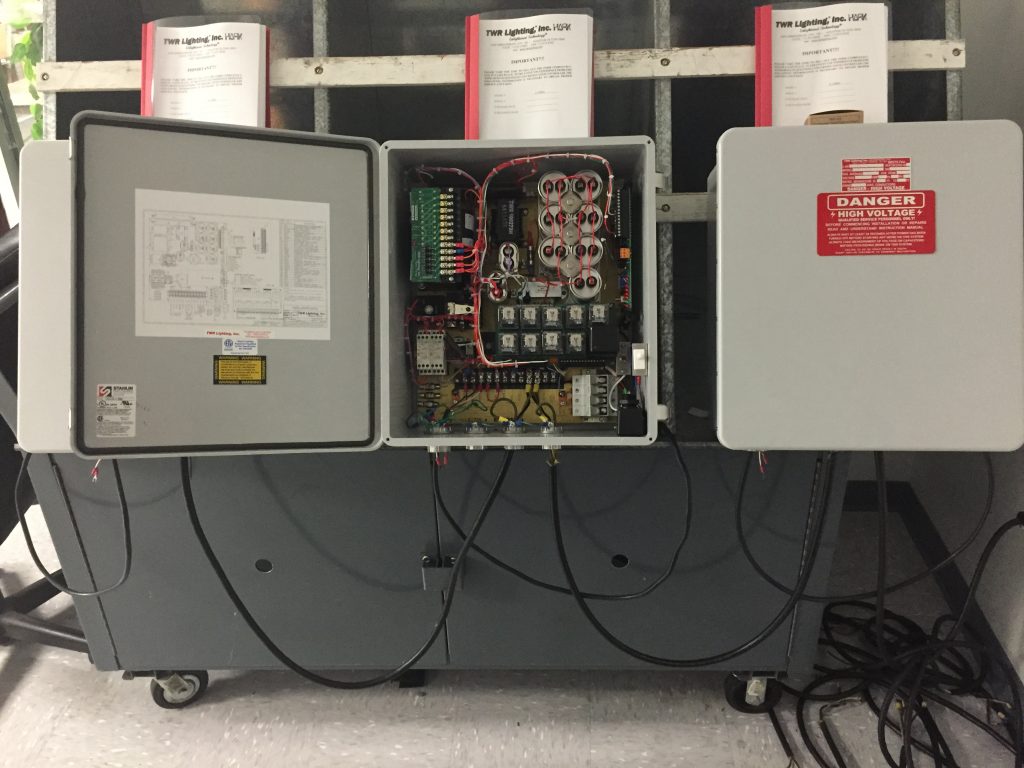

These same properties make fiberglass an excellent choice for use as electrical enclosures.

Proper selection of an enclosure begins by asking and answering the question:

“What are the requirements of my application?”

The many benefits of fiberglass enclosures make them a leading choice for applications featuring specific environmental or functional characteristics.

Stahlin® Enclosures pioneered the first fiberglass enclosure nearly 70 years ago and has been, ever since, the world’s leading manufacturer of fiberglass electrical, instrumentation, controls and industrial enclosures.

Fiberglass enclosures are ideally suited for:

Applications Requiring Corrosion And Chemical Resistance

Stahlin® fiberglass enclosures provide excellent corrosion and chemical resistance compared to metallics such as aluminum and painted or galvanized steel…and exceeds that of 316 stainless steel. With fiberglass, enclosure maintenance is virtually eliminated. Stahlin® fiberglass enclosures provide chemical resistance that exceeds all other major non-metallic alternatives.

Applications Where Ease of Modifications Is Important

Fiberglass enclosures are extremely easy to drill, punch and cut compared to all metals. Stahlin® fiberglass enclosures are lightweight and easy to handle compared to metal enclosures.

Applications Where UV Resistance Is Important

Because of natural resistance to UV degradation, non-haloginated fiberglass enclosures can weather the passage of time even in harsh exterior applications. All Stahlin® fiberglass enclosures are protected by SolarGuard®, a patented double protection formula proven in extensive comparison testing to outperform other available SMC formulations by as much as 60% in its ability to retain gloss and color after exposure to concentrated UV light. SolarGuard® provides an unsurpassed level of UV resistance, fire retardancy, chemical resistance and safe, durable performance…all without adding cost.

Rugged Applications Requiring Enclosure Strength

Fiberglass enclosures are robust and durable. Upon impact, metal enclosures are vulnerable to denting which, among other concerns, can compromise the integrity of the seal that protects everything housed within the enclosure.

Applications Where Installation And Labor Time Are Challenges

Fiberglass, compared with metallic enclosures, is lightweight, making it easier and quicker to install; thereby being of value in overall cost reduction.

Applications Using Wireless Technology

Fiberglass enclosures are ideal for protecting wireless technology because they allow wireless and radio frequency signals to pass unobstructed through the enclosure.

This allows you to have the antennas inside of the enclosure. Additionally, there is the option to block to EMI/RFI frequencies if needed, giving you more flexibility than metal enclosures.