About Stahlin Enclosures

For more than 70 years, Stahlin Enclosures has been a trusted leader in designing and manufacturing premium fiberglass, polycarbonate, and PVC non-metallic enclosures for a wide range of indoor and outdoor applications. Offering the industry’s most extensive selection of in-stock and customizable enclosures, we combine innovative engineering with strict compliance to NEMA, UL/CSA, and IEC standards. Proudly made in the USA, our enclosures deliver unmatched durability, aesthetics, and performance, making us the go-to choice for fiberglass, non-metallic, and polycarbonate enclosure solutions.

LEARN MORE

Industries Served

Stahlin Enclosures provides reliable fiberglass, non-metallic, and polycarbonate enclosure solutions for a diverse range of industries, ensuring durability and performance in even the harshest environments. From solar and wastewater treatment to agriculture, car washes, and utilities, our enclosures are designed to protect vital equipment. We also serve communications, lighting control, electrical equipment manufacturing, and the food and beverage industry with solutions that meet strict regulatory standards. Trusted by professionals in mining, oil and gas, and marine applications, Stahlin delivers robust, corrosion-resistant enclosures tailored to the unique challenges of each industry.

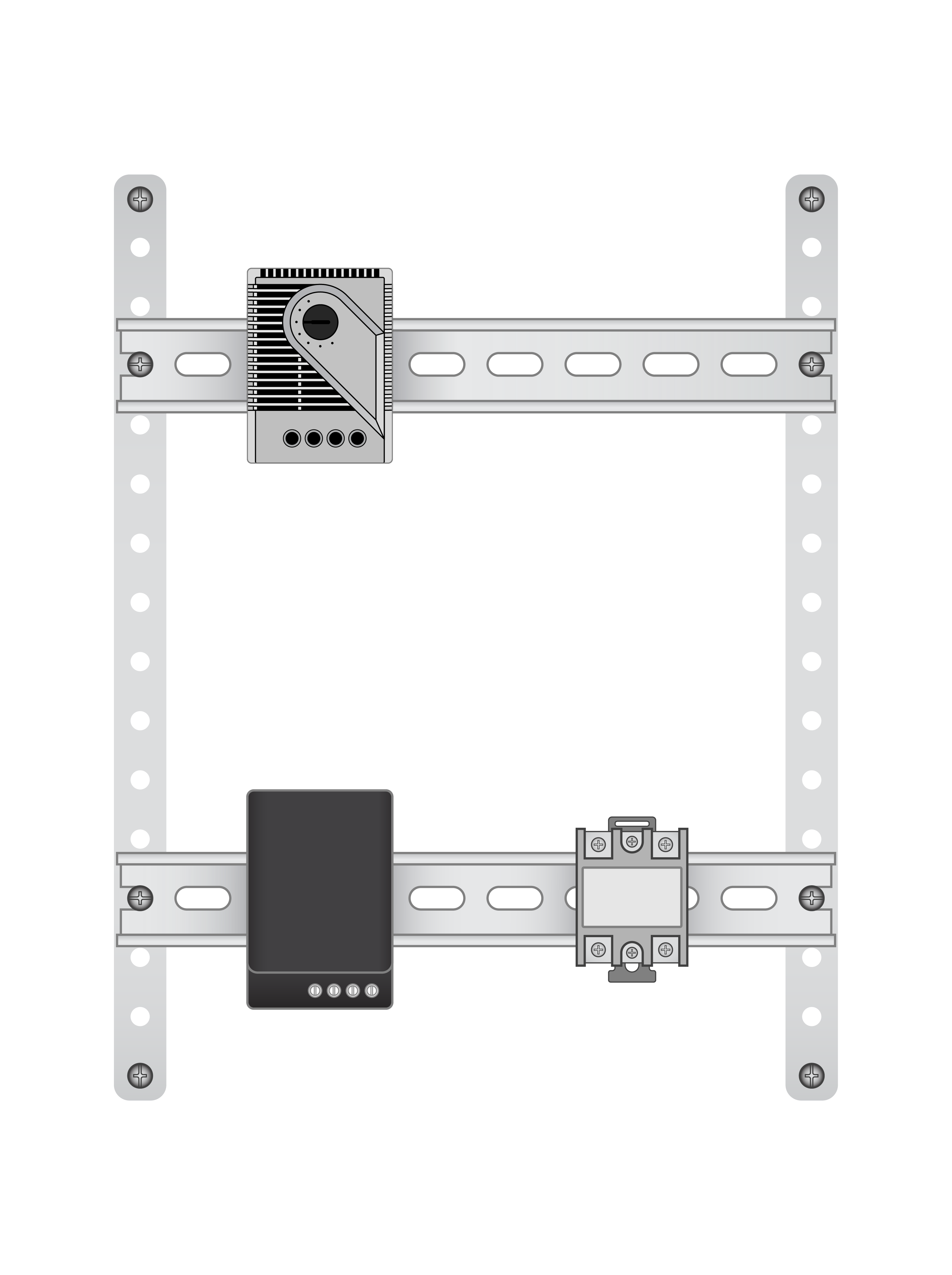

LEARN MOREModRight Modified Enclosures

We also provide our ModRight program: a service to engineers and designers for solving problems that standard off-the-shelf products cannot address. From custom designing nonmetallic enclosures to custom composite formulations, Stahlin has the technology and service support to help with even the most demanding applications.